Natural stones, the oldest known construction thousands of materials it has been used by people for years. Again Nowadays, natural stones, in various parts of structures and the architect is used for decorative purposes. This use as indoors and outdoors. We can divide. Outdoor wall cladding and as flooring material, stairs step, paving, cobblestone, curbstone and sculpture etc are used in artistic structures, interior flooring and coating material in bathroom and kitchen applications it is used.

Building blocks and marbles according to specifications and usage request transactions. Marble, Industry development and increasing demand in line with the new stone processing techniques have been improved and is presented to the liking. At first it was only cut, dimensioned and polished. When using marbles, these days are more natural different appearance and surface treatment marbles and natural stones are preferred.

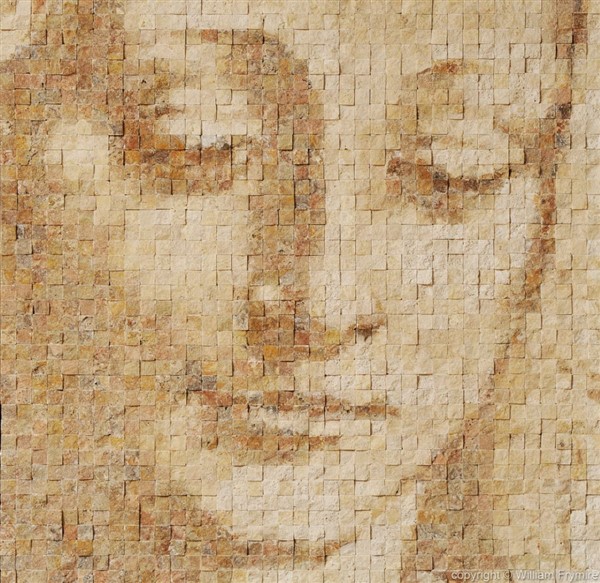

USAGE OF MARBLE

Natural stones used as marble according to the shape and surface treatments applied is divided into two.

1- Marbles Used After Polishing

After the natural stones are removed from the quarry, the use-up transactions. Stones brought from marble quarries desired thicknesses in marble processing plants .After cutting according to the place of use and feature sized. Then various abrasive and using chemical substances on the surfaces completely smooth by removing the roughness found and polished surfaces. Polishing capacity of marbles mineralogical It is closely related to the structure and size of the grain. all kinds of natural stones treated (marble, limestone, travertine, granite, serpentine, etc.) economic in the sense of marble is included in the definition (K, 2000).

2- Marbles Used Without Polishing

Some of the natural stones are also removed from nature.It is used. Natural stones extracted from the quarry in use, sized according to the desired properties and polished. This kind of natural stone use widespread. This kind of natural stones are granite,more like road, basalt, andesite, park, gardens used rocks occur.Also fireplace, barbecue and building finishing and garden wall coverings used in tuff, tuffite,sist and similar rocks fall into this class. (Kun, 2000).

SURFACE SHAPING TECHNIQUES

With hundreds of varieties and colors marble industry since ancient times specific cut and polished stones It is used. Modern architectural applications With all kinds of natural stone marble and natural close to nature and unpolished is becoming increasingly common. This is other than classical polishing method development of surface treatment techniques is mandatory has made. Various technologies for this purpose marble surfaces different methods for shaping. It is applied. Filling some of them compulsory transactions.

The vast majority is special request and natural appearance It has increased. Applied in marble and natural stones

surface treatment techniques can be listed as follows:

– Saw cutting (Sawn cut)

The first process applied in marble is cutting. Marble and natural stone blocks, processing plants it is cut into plates of various thicknesses. Some natural stones are used in this way as well as the first cut. Smooth plate surfaces of the stone yet no machining circular saws cutting marks. Cut like this plates are called “raw plates”. Marble All operations to be applied to the surfaces of this plate surfaces and saw marks as a result.

–Honing

Honing (matt polished) process with cut plate surfaces with abrasives of various sizes. abrasion is the removal of roughness. Honing depending on the desired degree of opacity 240, 320 or Smearing is done up to 3/4 grains. This operation abrasion traces are removed as a result, and then “mat lacquer abrasivi” (bristle felt) is used. As a result of honing process smooth, smooth and a relatively bright surface is obtained. However polished and polished marble does not reflect light like surfaces. Therefore natural colors of honed marbles polished does not look as effective as marbles and colors of colored marbles close together shows similar haracteristics. Polished and bright flooring, stairs and pool edge coatings. It is. Anti-slip as the surface is unpolished and a safe walk. Hohl Game process is generally used, despite all the it is applied to marbles that do not receive polish.

–Polished

Polishing process with different composition and hardness suitable for the purpose of abrasives and chemical fluxes as a result of sequential and common use It is provided. Usually between 80 and 600 mesh numbered abrasives and finally polish stone (Ozulogul and Erdogan 1995). However, more sensitive and 36 to 1200 mesh on problematic stones abrasives are used. Stone surface remove very small burrs of several microns abrasives containing “oxalic acid” It is used.

* Perfectly smooth of marble surfaces be and giving brightness, made for this process marble which is well crystallized and small crystalline polishes the surfaces better. polished reflection of light from surfaces does not originate from a substance. Brightness and light natural crystal of marbles directly in the reflection structure. Because marbles each of the crystal grains surface polishing until a smooth surface is obtained cut. Thus, the surface roughness or completely removed or minimized. Result polished marble falling light, by uneven surface it is fully reflected back. Thus a polished surface, marble color and color depth more makes it well visible. A porous stone quality of the polishing process It does not affect. This process is applied to the surface of the stone. Against atmospheric and chemical effects makes it more durable. But busy peopleand where there is vehicle traffic. If adequate maintenance is not performed, the brightness will gradually it disappears.

–Flamed

Flame combustion process different thermal expansion mineral applied to rocks. Therefore usually igneous rocks is an applied process. Especially in granite quartz minerals behavior, granite surfaces of this process effective allows. Calcium carbonate origin resistant to high temperatures of marbles this process is not applicable. Even some granites with iron in the composition process may not be appropriate.

–Tumbled (patinato)

In recent years, antique-looking marble speed of tumbling works due to intense interest. It has won. Some types of marble surfaces rough parts (waist cm «30×30cm) to a worn and worn image. It is a process applied to attain. Marble pieces, thickness and various sizes of square or cut into rectangular shapes. Tumbled Stones location of sharp surfaces at edges and corners a more rounded profile. Tumbled with small pieces. Burning at the same time resulting in reduced colors. that on the surface of the stone a structure is formed. This structure slips especially external places, walkways and sidewalks preferred it is. But as a result of surface treatment stone stone with some reduction in strength surface is exposed to various impurities It is concerned. Therefore, necessary measures it should be taken. Flame burning machines in many different ways has been designed. Using method of hammering machines are the same. Some of them are automatic water cooling systems. Some models are both at the beginning and at the final stage of cleaning and brushing systems. There are saw marks on the cutting. If you wear if the operation cannot be performed well enough, does not disappear. Tumbled marble polished or matte indoors and outdoors used for decoration and ornamental purposes. movements – as in the automatic polishing line – rubbing in turn. Meanwhile, the soft surface some sawdust is removed from the areas.

–Sand Blaster

Marble surfaces matte – glossy rough appearance and different patterns for the creation. In this process water and sand mixture, high-pressure marble surface spraying or automatic sandblasting machines used. Sand grains on marble surface and / or impact of the blasting nozzles very small dots and bumps in spots creates. Thus, marble surfaces rough and wins an ancient image.

– Hammering (Bush Hammered)

Taking the necessary measures in the hammering method on all types of marble and natural stones although it is a method that can be applied usually with volcanics such as basalt, andesite gives better results in tuffs. Stone surface embossed to give. Often historic buildings Due to the structure style of this medical buildings is preferred as facade coating.’ hammering process manually or with the help of automatic machines done. This medicine surface created marbles it does not slip even in the wet. hammering they are exposed to intense pollution. Rough surface pollution is also difficult to clean. Protective coating for these surfaces substances should be used. This is both the surface it prevents contamination and become prominent. Increasing surface forming sandblasting process machines.

– Filled

Formation of a portion of natural stones there are pores of various sizes caused by. As a result of cutting and polishing pores become more pronounced ~ and move »these stones are artificial, fill and close the pores in stone filling process is usually done in special type machines. Some types of machines in the form of baked d’olgu line calibration, pre-cleaning,

drying, filling, baking and polishing on a line. In order to fill the pores polyester based and cement compound filler used ingredients. However filler pore liquid or fluid according to the diameter. Stylish filler for small and small pores sparse and coarse pores solid filler is used. Transparent the filling of the stones should be transparent. Used the color of the filler must be the same with the original color. Otherwise move also known as some building blocks on the surface of the black colored dendritic structure gives fossil appearance.

Aesthetic-looking decoration material in buildings and countries such as Germany, Austria roofing instead of roof tiles slates are used as atmospheric effects and abrasion resistant and not porous.

–Natural cleft

Slates gained during metamorphism cleavage is made throughout smooth surfaces they divided. Naturally separated layer surfaces rough structure slate move as an aesthetic coating material, window edges, sills and floor tiles used. In these embodiments, natural or are used in dimensional shapes. It’s yam building block also random size and brick

used as cut to size seen.

–Acid washing (Antico / acid washed)

An ancient image of rough marble surfaces is made to take. Calcium carbonate compound marbles are very sensitive to acids. This marble surfaces acidic compounds applied to the surface roughness smooth they produce a wavy surface. This is prevent marbles from slipping during walking is a structure. However, this type of marbles maintenance and cleaning is more difficult than others. Same a variety of chemical structure of stone at the time recommended due to the formation of reactions is not a method.

RESOURCES

Steel, MY, 2000. Marble Geology Lecture Notes. BATTERY. Afyon Vocational School Marble Technology

Program. (Unpublished). Opium. Kun, N., 2000. Marble Geology and Technology. Tezer Printing House. Izmir.

Ozulogul, A., Erdogan, M., 1995. In the marble surface brightness by image analysis method measurement. 1st Marble Symposium Proceedings

The book p. 37-44. Opium, Set Machine Brochures, Marmomacchine Pellegrini Srl. (Translated by M ^ Adnan Saraçoğlu).

We hope that you have enjoyed reading this blog and checking our wall cladding & travertine splitface collection. You can follow us on our active instagram to check our products we supply.

Please keep in mind that with our experienced stone experts we also provide stone inspection services for your orders from other factories anywhere in Turkey.

Please do not hesitate to contact us for your inquiries:

Email | Instagram | Facebook | Whatsapp

Adress: Kocabaş Mahallesi, Ankara Bulvarı No: 123 – (Petrol Ofisi Yanı) – Denizli, TURKEY